Full Tang Integral Damascus Gyuto w/ Mammoth tooth and Koa Available October 12th

CommentStainless Damascus K-Tip Gyuto Available October 12th

CommentCustom Integral Damascus Santoku

CommentIntegral Raindrop Damascus Santoku

Curly Hawaiian Koa with carbon fiber inlay.

Two Stainless Damascus Gyutos Headed for the Store 8/31/2018

CommentCustom Damascus Integral Banno Bunka

CommentBanno Bunka integral in Midnight Ripple Damascus and Ironwood Burl.

Custom Damascus Usuba Kamagata

CommentCustom integral raindrop damascus usuba kamagata. Carbon fiber handle inlayed with yellow mammoth tooth and pure nickel capped with a faceted damascus butt cap. The saya is carbon fiber milled to matched usuba grind and lined with supple pig skin. The saya is asymmetrical to match the blade and inlayed with matching mammoth. Feather damascus keeper pin keeps the blade snug and protected.

Custom Stainless Damascus San Mai Gyuto

CommentI forged this custom gyuto with a stainless raindrop damascus jacket and a stainless core. The handle is carbon fiber blue mammoth tooth and spalted jatoba. The saya is full carbon fiber with a leather liner and a faceted titanium keeper pin.

Custom Stainless Damascus Gyuto

CommentI forged the chevron damascus blade from CPM154 and AEB-L. The stainless chevron gyuto is handled in a stainless damascus bolster, carbon fiber spacers, Tasmanian blackwood, and capped with stainless damascus. The saya is curly claro walnut with a pigskin liner and features a stainless dammy keeper pin.

Integral Damascus Yanagiba

CommentCustom Western Damascus Integral

Comment225mm, 375 layer damascus integral gyuto with a nickel silver spacer and an ironwood handle.

Holiday Treat #4

CommentHere's a video from my perspective using the power hammer to forge weld and draw out a billet. This weld a draw totals the layer count at 184 with the next session totaling 1104 layers.

Holiday Treat #3

CommentHere is the start to a Bold Midnight Ripple Damascus gyuto and parer:

The completed custom parer and gyuto:

Holiday Treat #2

CommentUp next is a damascus gyuto/chef, damascus petty, and a monosteel Western integral. The two matching damascus blades will be receiving carbon fiber and ironwood handles. The Western integral will be getting a carbon fiber handle.

Damascus petty and gyuto with an integral Western gyuto.

The damascus gyuto ready for the carbon fiber and ironwood shoes.

Holiday Treat #1

CommentFinal step in rounding the coil and spine is using a little shoe polish action with 1k and then 2k paper.

The core steel, 52100 high carbon is laminated with a jacket totaling 750 layers creating a super fine damascus pattern. This will be available for sale.

Custom Titanium and Carbon Fiber Moribashi

CommentNew Store Knives

CommentThe first gyuto is a hand forged damascus integral handled in rosewood burl. This gyuto is one of a kind. Available 14 October.

The second gyuto is a multi-bar damascus featuring two "W" patterns for a unique combination of swirls and curls. The blade is handled in my mokume-gane and a stunning piece of rosewood burl to compliment the damascus. Available 14 October.

Start of a Honyaki Damascus Integral Gyuto

CommentCustom Damascus and Mokume-gane Kiritsuke Work in Progress

CommentExhibition grade rosewood burl.

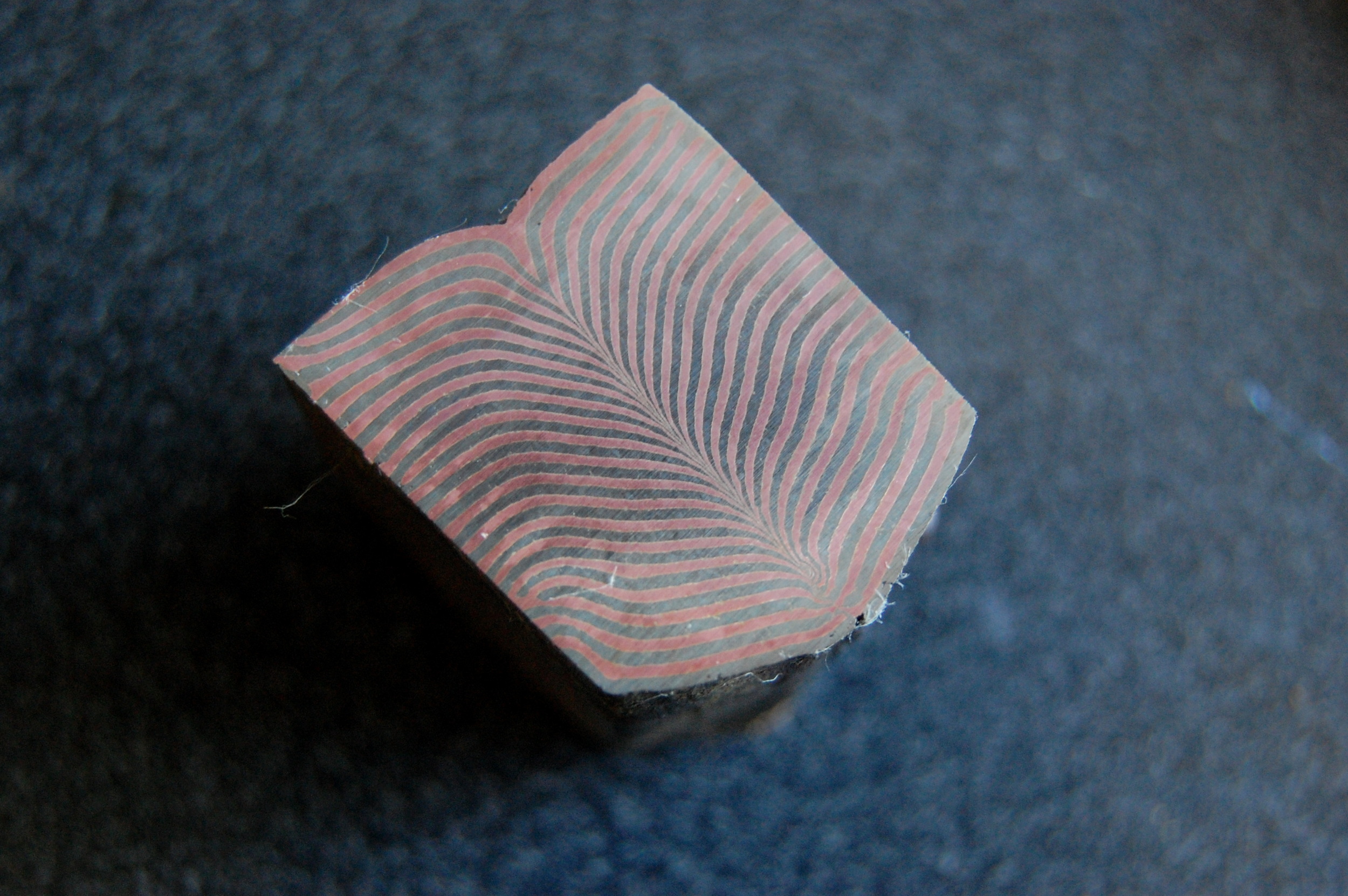

Copper and nickel silver for the mokume-gane.

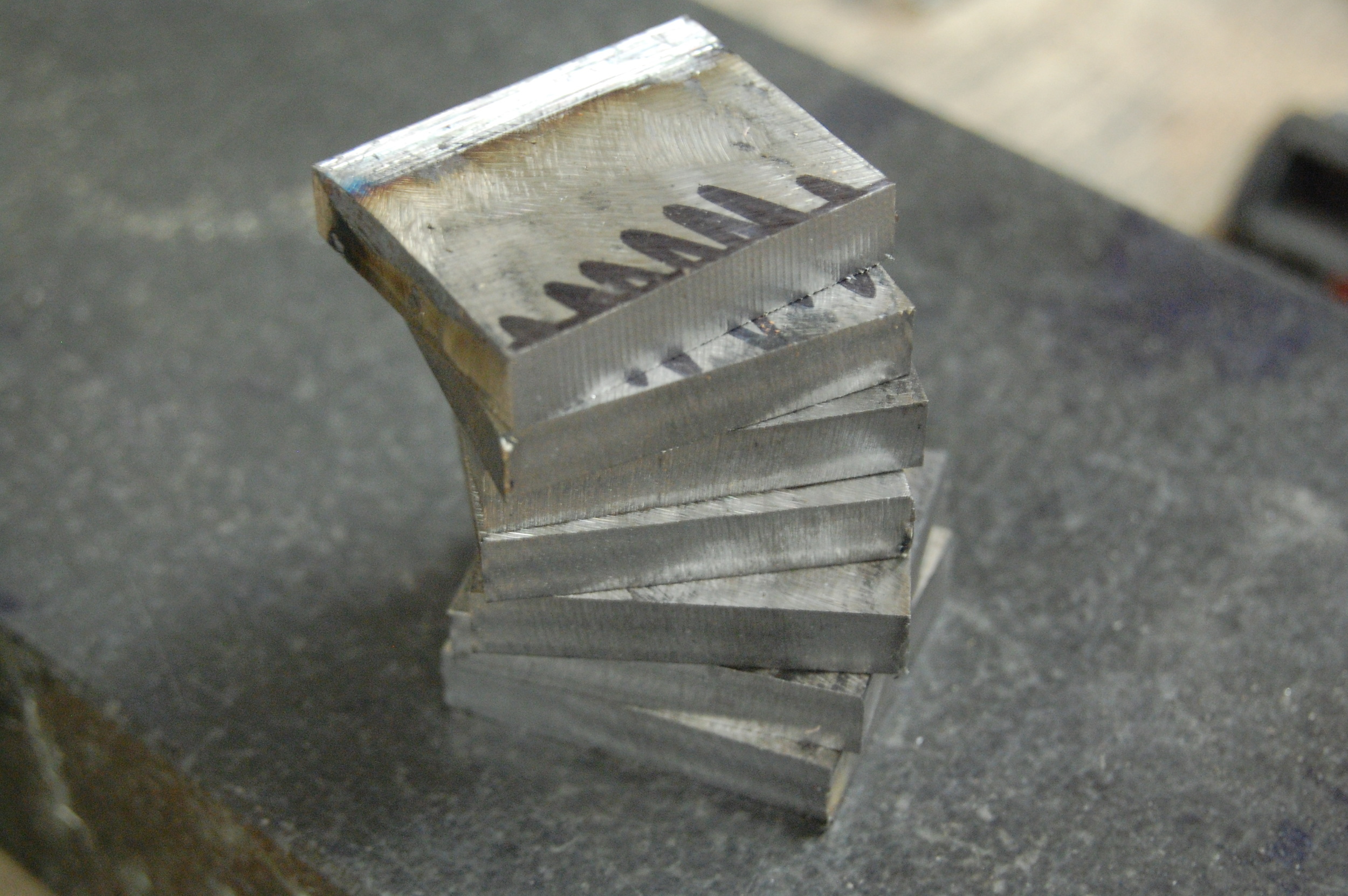

A billet that I forge welded and is currently at 88 layers of 52100 and 15N20.

The bar is cut up in seven sections for a layer count of 616.

The seven layers have been forge welded and cut down the center to create the blade pattern.

The two billet sections are forge welded back together and forged out to a basic shape.

I annealed, trimmed, and gave the blade a quick etch to check the pattern.

The blade has been heat treated and the ura has been ground on the backside.

Working on the front.

The blade has been finish ground, stone work to double check everything, and hand finished. After hand finishing, the blade was etched and my makers mark was applied.

I wanted to have a matching pattern for the bolster and butt cap so I made mokume-gane to match the feather pattern.

The finished kiritsuke.

Feather mokume-gane polished.

Damascus Yanagiba and Gyuto Set

3 CommentsWave damascus, mokume, 5720 year old bog oak, and snake wood for this set.