Exhibition grade rosewood burl.

Copper and nickel silver for the mokume-gane.

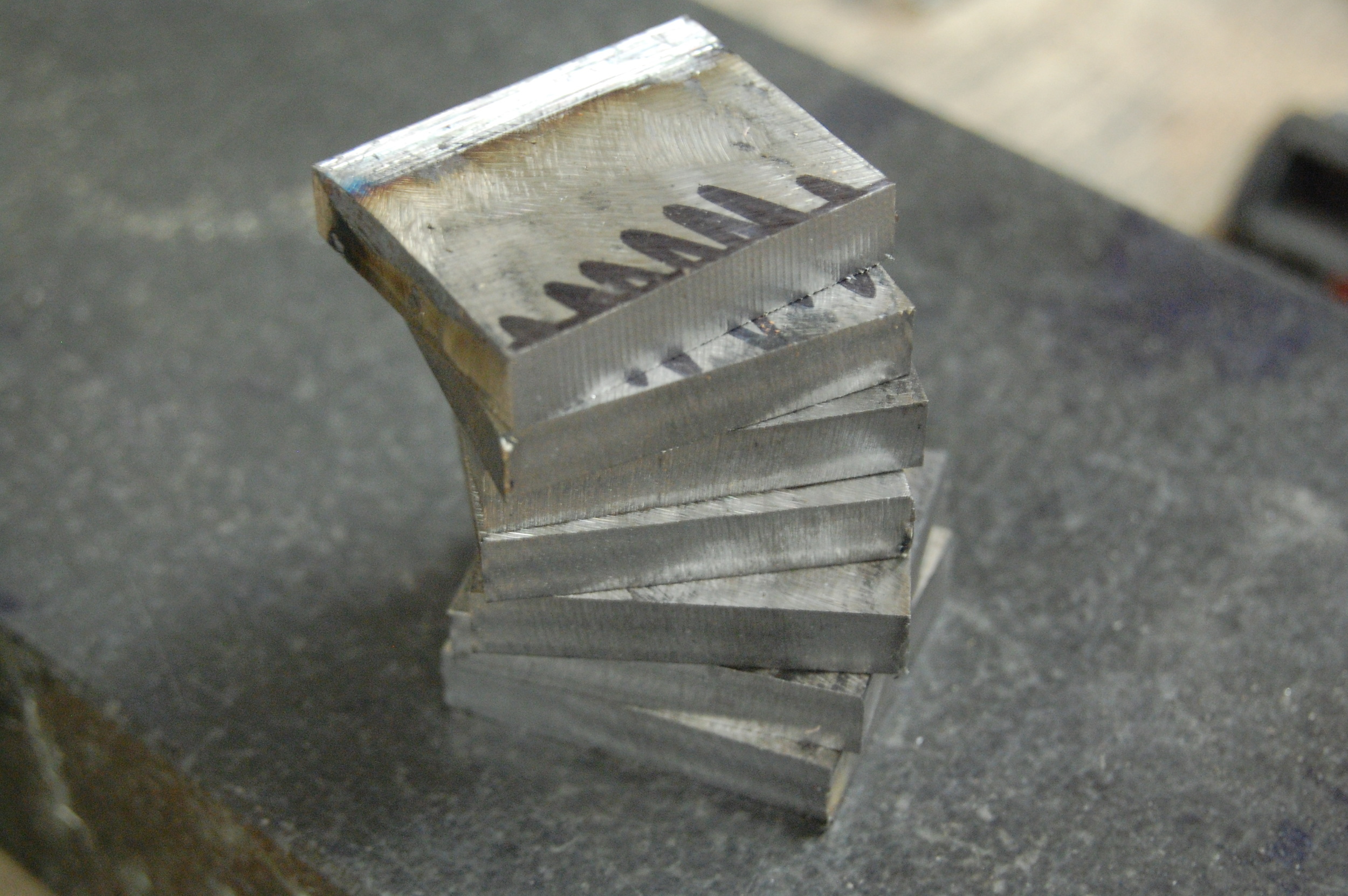

A billet that I forge welded and is currently at 88 layers of 52100 and 15N20.

The bar is cut up in seven sections for a layer count of 616.

The seven layers have been forge welded and cut down the center to create the blade pattern.

The two billet sections are forge welded back together and forged out to a basic shape.

I annealed, trimmed, and gave the blade a quick etch to check the pattern.

The blade has been heat treated and the ura has been ground on the backside.

Working on the front.

The blade has been finish ground, stone work to double check everything, and hand finished. After hand finishing, the blade was etched and my makers mark was applied.

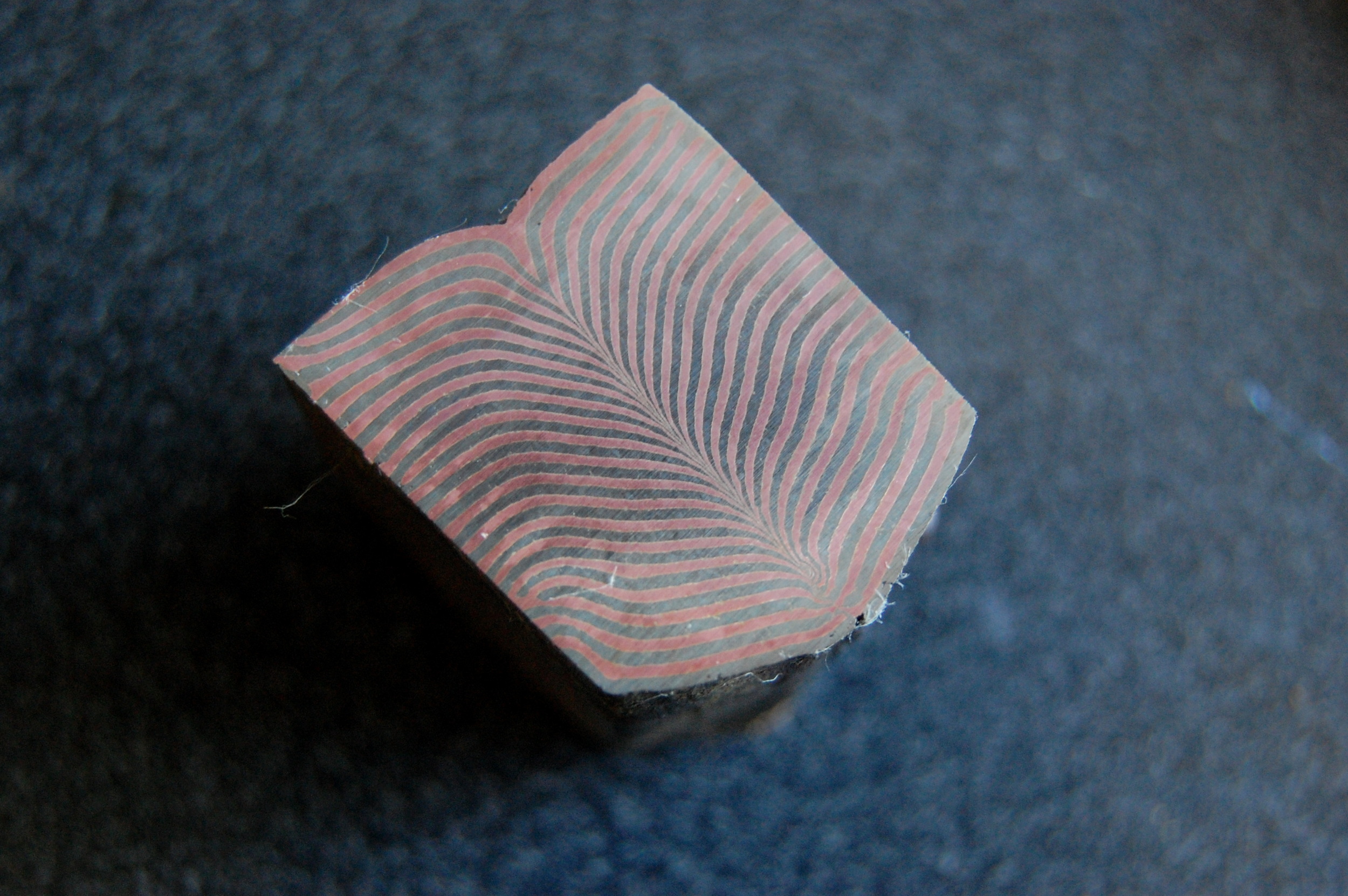

I wanted to have a matching pattern for the bolster and butt cap so I made mokume-gane to match the feather pattern.

The finished kiritsuke.

Feather mokume-gane polished.